Technology

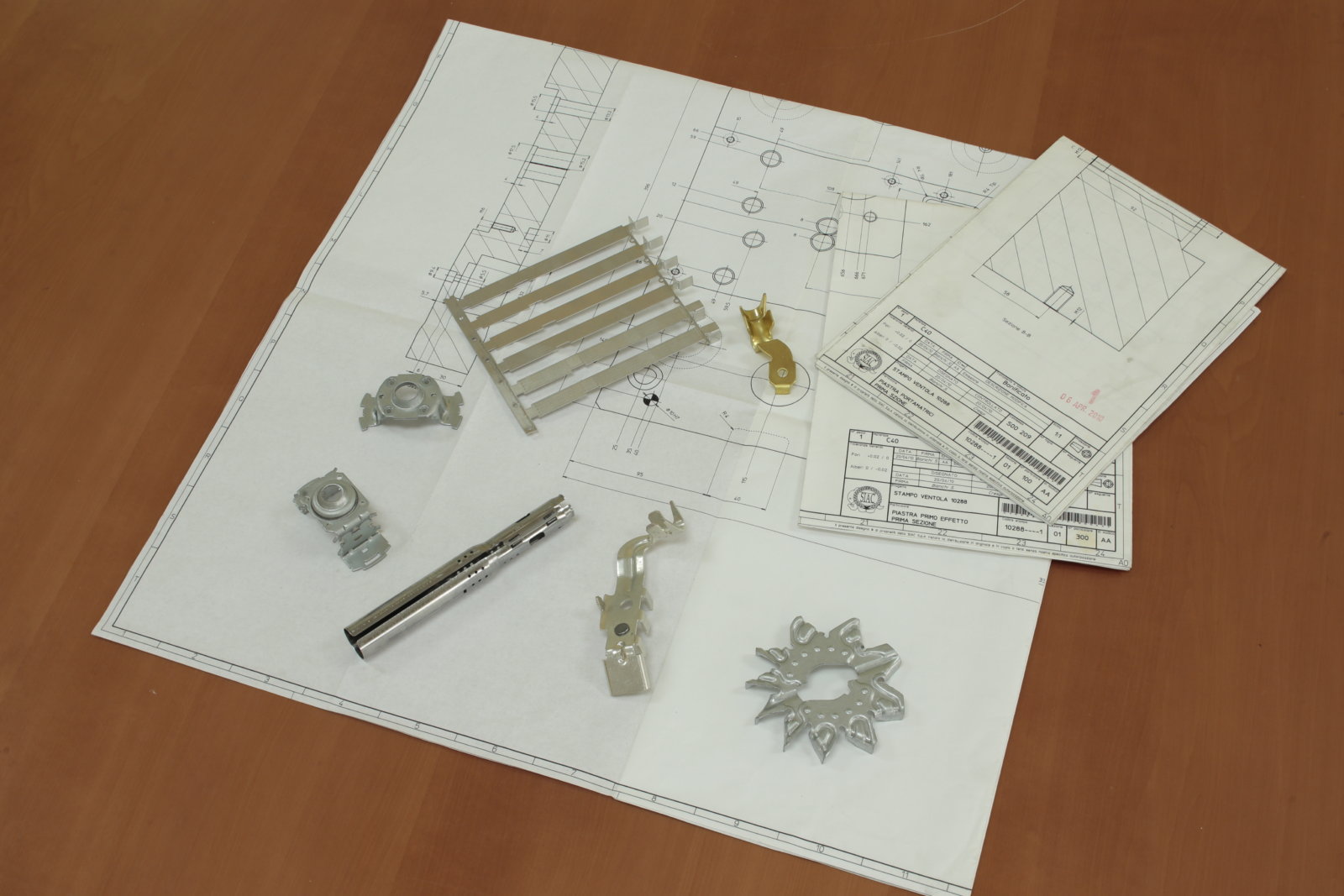

Design

After receiving the order from the customer, our production process begins.

The technical office analyzes the feasibility of the project, studies the equipment to be built internally or any changes to equipment designed by customers, offering a support as a co-designer.

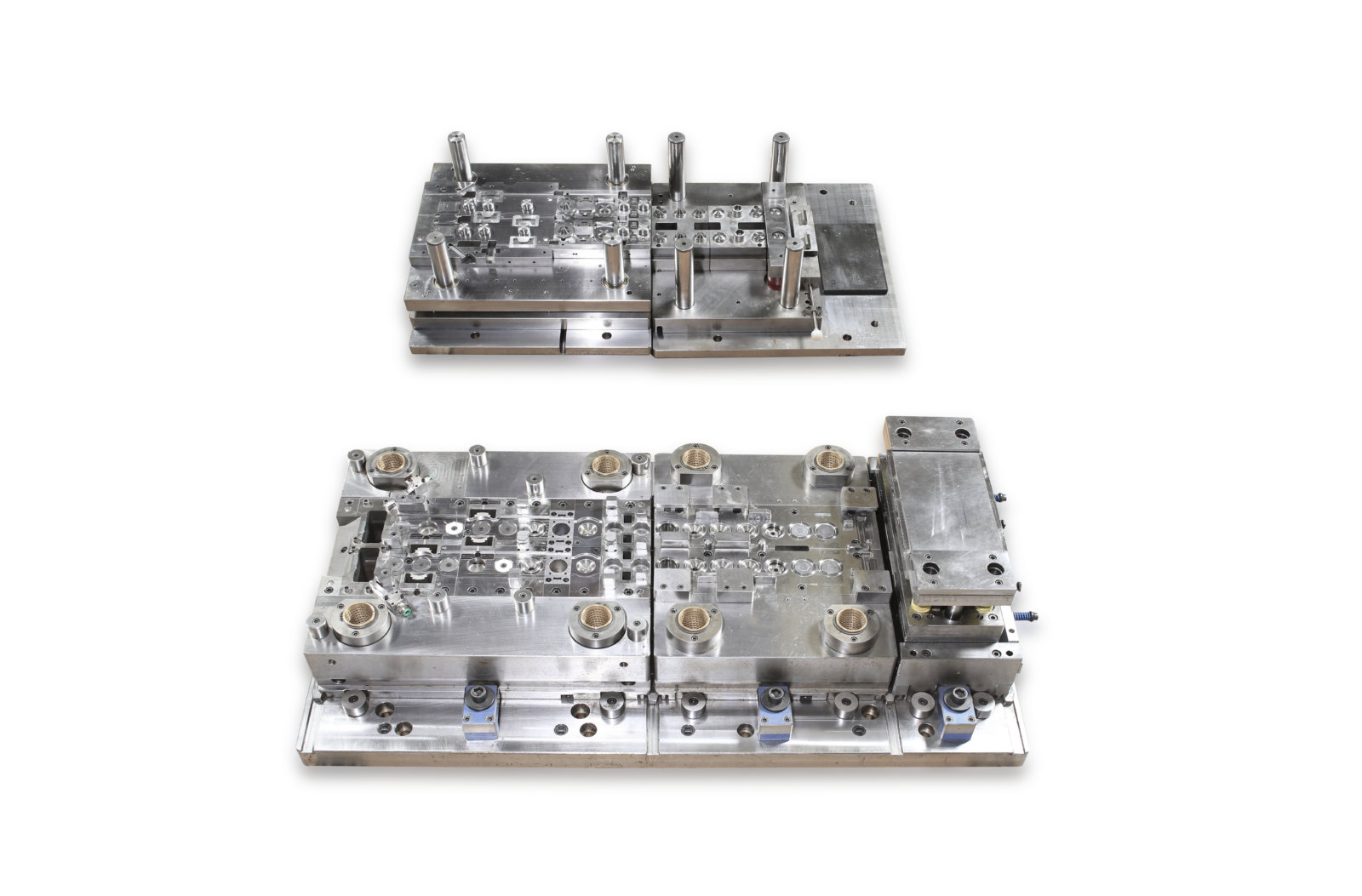

Stamping Technology

Once the project has been realized, the next phase of internal construction of complete tools and relative maintenance is carried out, supported by a deep know-how in terms of product development and production.

The molds made can be: progressive tools, deep drawing tools and modular tools.

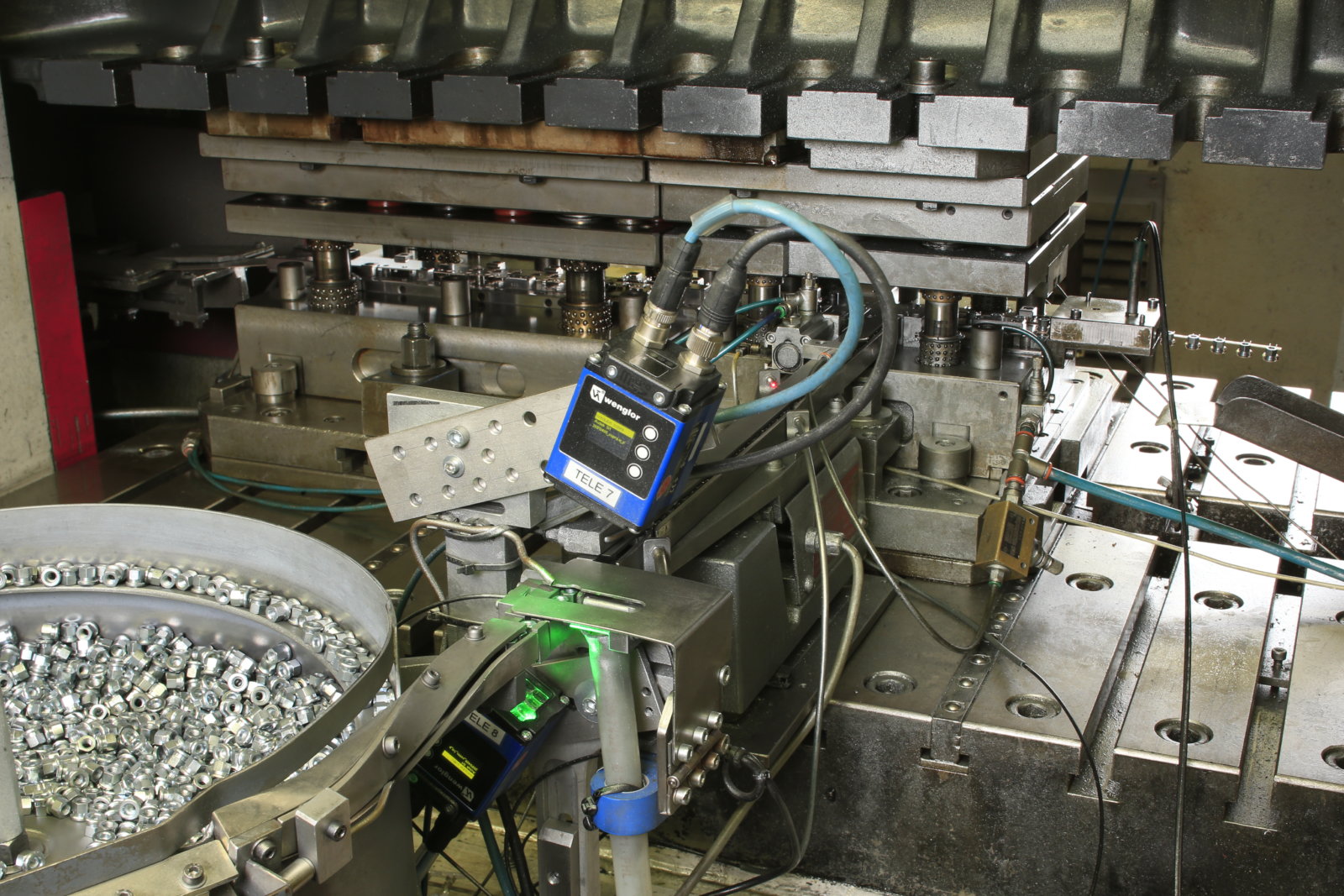

Stamping

The product can be produced by stamping, blanking, cold drawing with machine washing, using presses and transfer machines, such as:

• 45 Bruderer

• 30 Balconi

• 10 Transfer

• 3 Yamada

• 3 Schuler

• 2 Minster

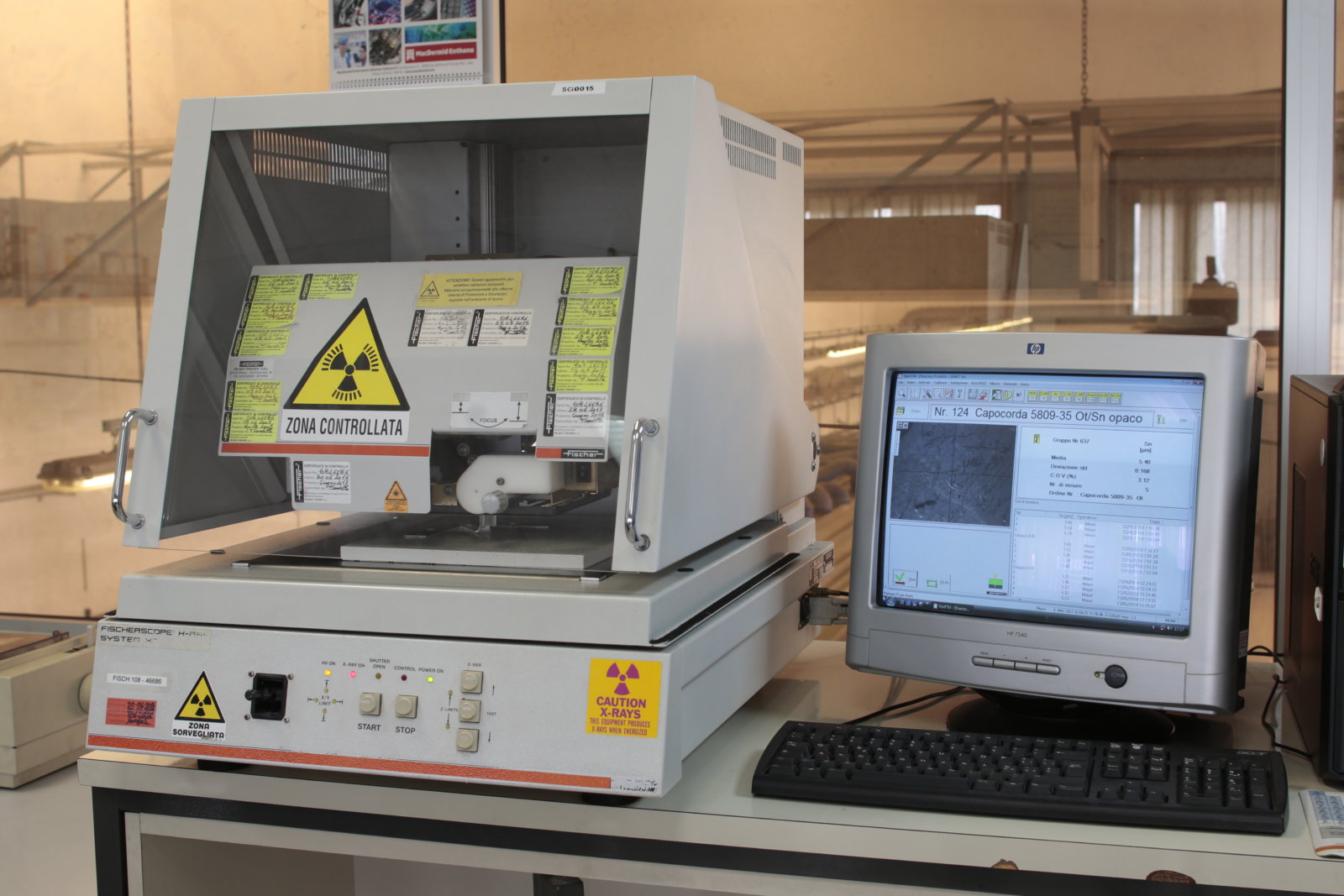

Galvanic process

The product can be treated superficially through:

- Tumbling

- Phosphatizing

- Ultrasound washing

- Nickel plating

- Copper and brass plating

- Tin plating

- Painting

- Zinc plating

Machining:

Other work can be:

- Mechanical machining on CNC (milling, drilling, threads)

- Turning

- Grinding

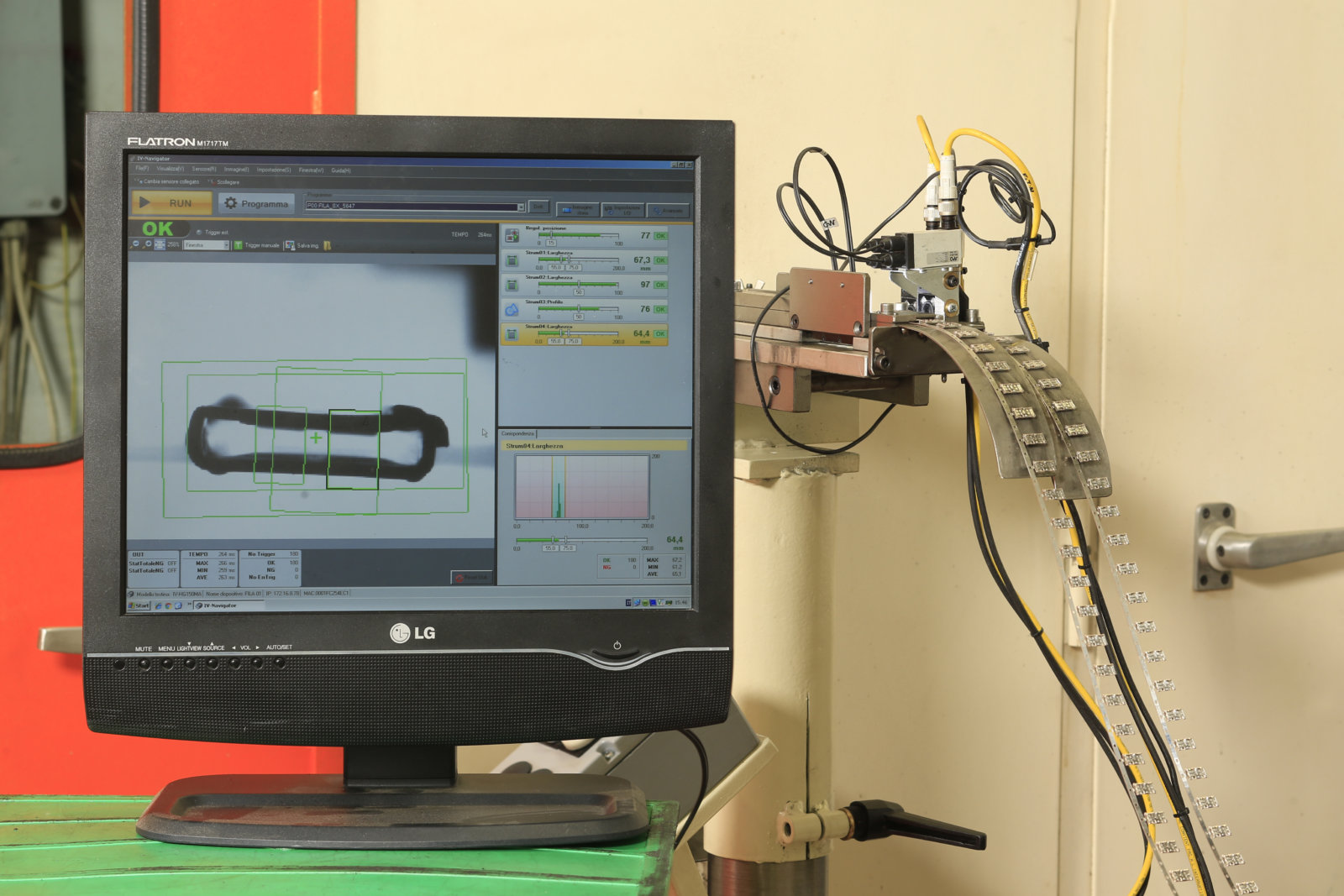

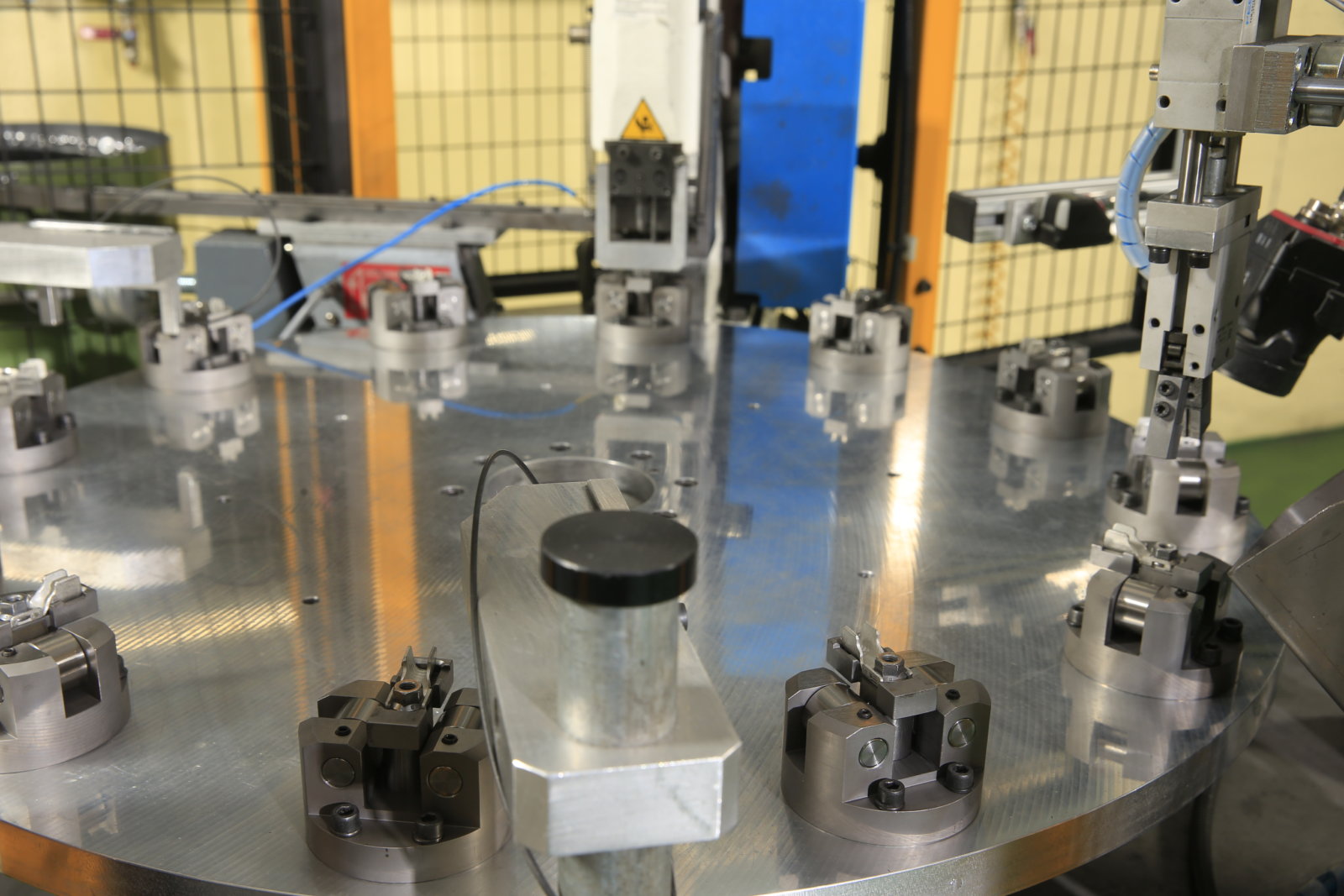

Assembly

IAMET has a department dedicated to the assembly of products, equipped with automatic control systems.

packaging:

- Weighing

- Packaging