Manufacturing

PRODUCTION PROCESS

The entire hot-forging production cycle is carried out in-house, from cutting the bar to the sandblasting phase. We team up with specialized external suppliers for machining and other surface treatments.

MATERIALS AND ALLOYS

We are able to produce parts in the most common brass, copper and aluminium alloys. The table below details the most commons alloys used:

Leghe di ottone | Nome commerciale | Composizione chimica |

CW617N | OT58 | CuZn40Pbi2 |

CW612N | Profondo stampaggio | CuZn39Pb2 |

CW508L | OT63 | CuZn37 |

CW509L | Lega Muntz | CuZn40 |

CW602N | ADZ | CuZn36Pb2As |

CW610N | Lega Muntz al Pb | CuZn39Pb0,5 |

CW626N | DZR Brass | CuZn33Pb1,5AIAs |

CW719R | Naval brass | CuZn39Sn1 |

CW510L | OT57 (Pb < 0,2 %) | CuZn42 |

CW510L-80 PPM | OT57 (Pb < 0,008 %) | CuZn42 |

CW511L | OT57 - USA | CuZn21Si3P |

CW724R | EcoBrass | CuZn21Si3P |

Leghe di rame | Nome commerciale | Composizione chimica |

W004A - E-Cu 57 - CW024A | Cu - ETP | Cu > 99,85% |

Leghe di alluminio | Nome commerciale | Composizione chimica |

AI 6082 | EN AW 6082-T6 | AlSi1MgMn |

ASK FOR A QUOTE

MACHINERY

Our machinery comprises several forging machines, both presses and screwpresses.

All production lines are completely automated, with electric-actuated load and discharge devices.

One of the forging lines is equipped with a robot managing every stage of the forging (die lubrication, load and unload of the parts), in order to attain the highest possible quality even for parts with complex shapes or heavy weights.

In addition to the forging machines the division also has blanking machines, automatic sawing machines and sandblasting machines, with steel or inox grit.

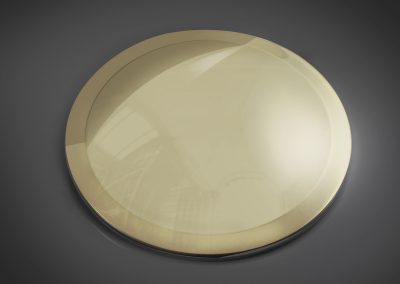

PRODUCTS

The division manufactures parts according to the customer’s design.

Depending on the technical features of the part the most suitable forging method and machine are selected. Thanks to its flexible machinery the division is able to forge everykind of parts: from the simplest ones, forged with high production rate, to the most complex parts, with weights ranging from 50 grams up to 15 kg.

The sandblasting of the parts is carried out in-house, also with inox grit if needed.

For other surface finishes we rely on external suppliers, performing treatments such as:

- Pickling

- Nickel and chrome plating

- Brushing and polishing

- Brassing

- Tumbling

Other treatments are available upon request.

In the gallery below are shown some of the parts we manufacture.