Quality

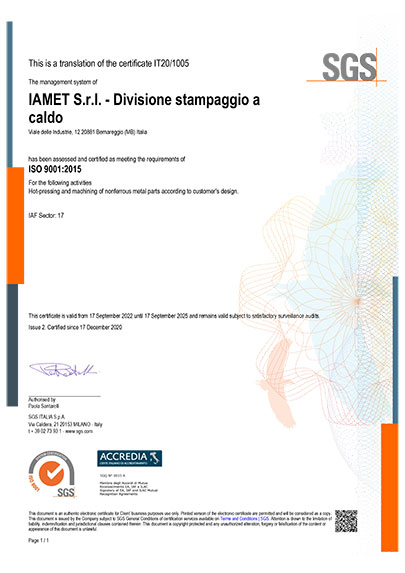

WE ARE ISO 9001 CERTIFIED SINCE SEPTEMBER 2004

We value customer satisfaction as the fundamental target to be achieved.

The division, together with the client, defines the main characteristics to be measured and kept under control during the manufacturing process.

By means of a constant collaboration between customer and supplier all the acceptability criteria are set, with reference to international standards, technical drawings, control plans and additional requirements by the client.

The division supplies also quality control reports comprising dimensional report analyses, material traceability data and, on request, capability studies (detailing Cp, Cpk, Cm) and SPC (Statistical Process Control) data analyses.

These analyses are carried out in addition to the quality checks performed during each stage of the manufacturing process, such as production start-up approval, quality control during the forging process, final inspection for outgoing goods.

Our set of quality control instruments (calipers, micrometers etc) has been reinforced with a 3D CMM (Coordinate-Measuring Machine) fitted with optical scope and touch probe.

Download the following certifications:

• ISO 9001 Certificate [pdf]